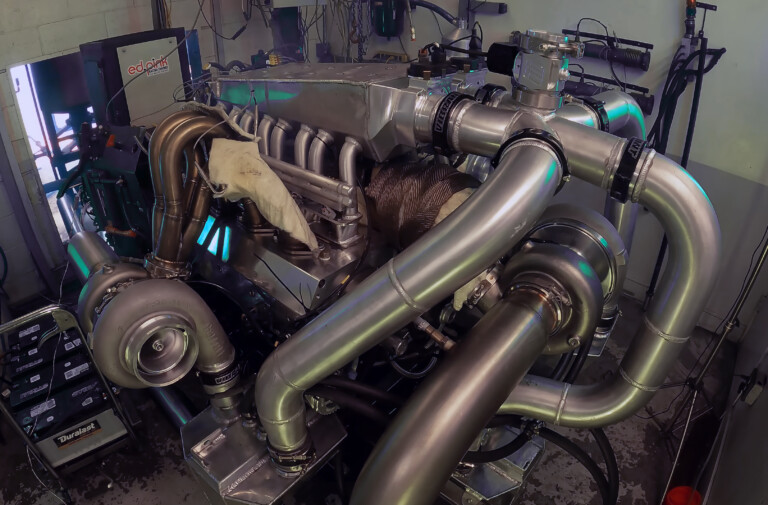

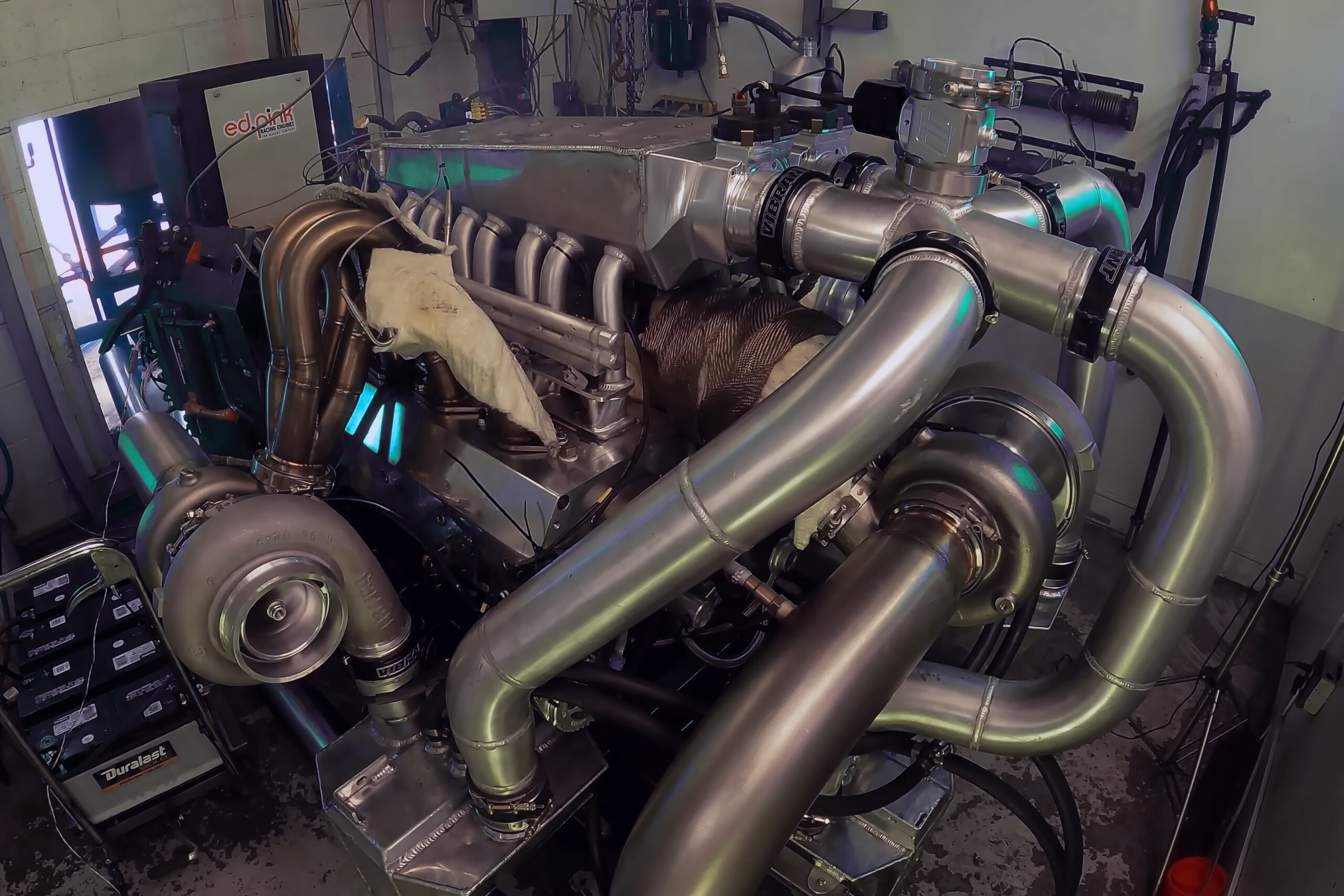

A while back, we set out to see how cheaply we could make 1,000 horsepower in a reliable package. The goal was 1,000 horsepower for $8,000 (hence the “1K For 8K” name), and while we achieved our power goal, we came up about $1,700 short of the goal. The engine ran great. So great, in fact, we decided to use it as a test mule for another project we had bouncing around in our heads. Dubbed “Project 007” (due to the serial number of the BoostLine Performance short-block), we headed back to KPE Racing with a ProCharger P-1X blower kit, intent on really leaning on the blower. We typically trend towards larger units, and were pretty interested to see what we could do with a smaller supercharger on our budget 5.3-liter LS engine.

Manufacturers rate superchargers with a maximum horsepower rating based on the efficiency of the impeller. However, if you’re planning a build near the maximum output of a specific supercharger model, common sense says to go up a step or two in size. It’s a practical consideration that means we don’t often get to see superchargers truly maxed out. Since we seem to have an affinity for pushing boundaries, our goal was simple: see what it takes to max out the P-1X.

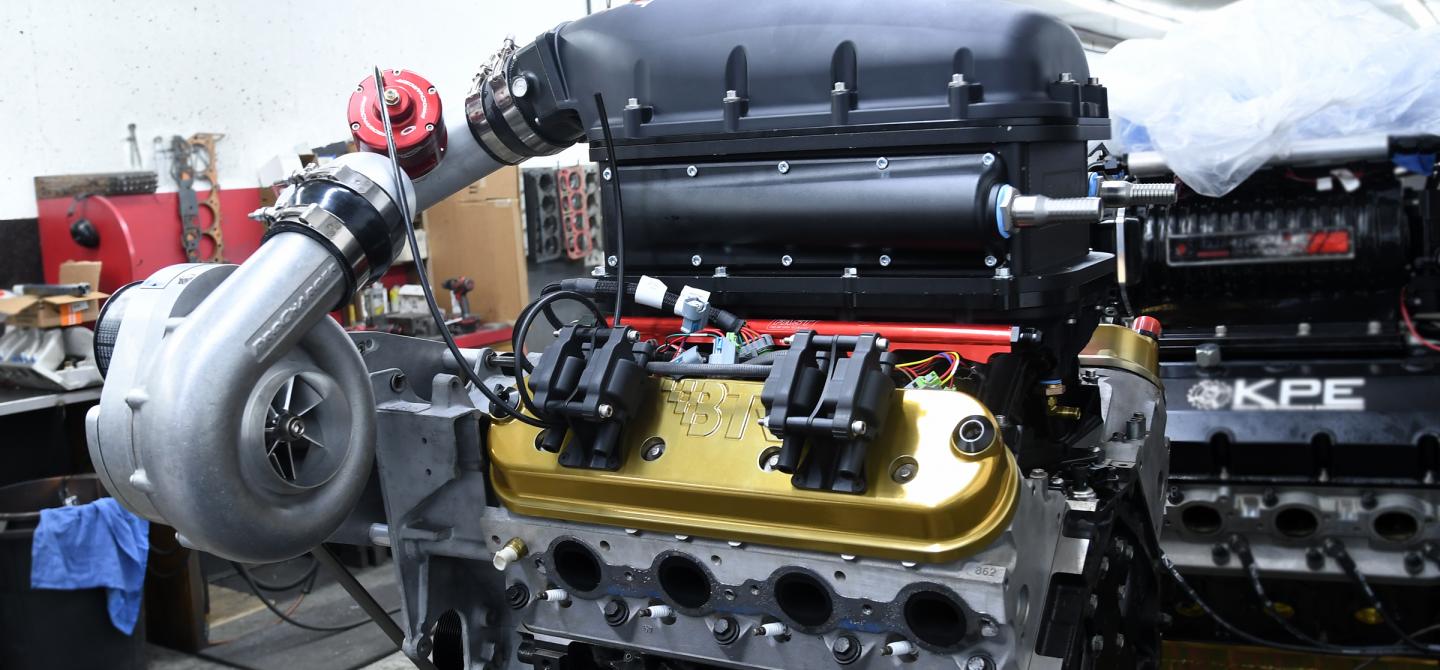

The star of the show in this test: the ProCharger P-1X. Capable of 950 horsepower and 65,000 rpm, this is the baddest blower in the P-series lineup.

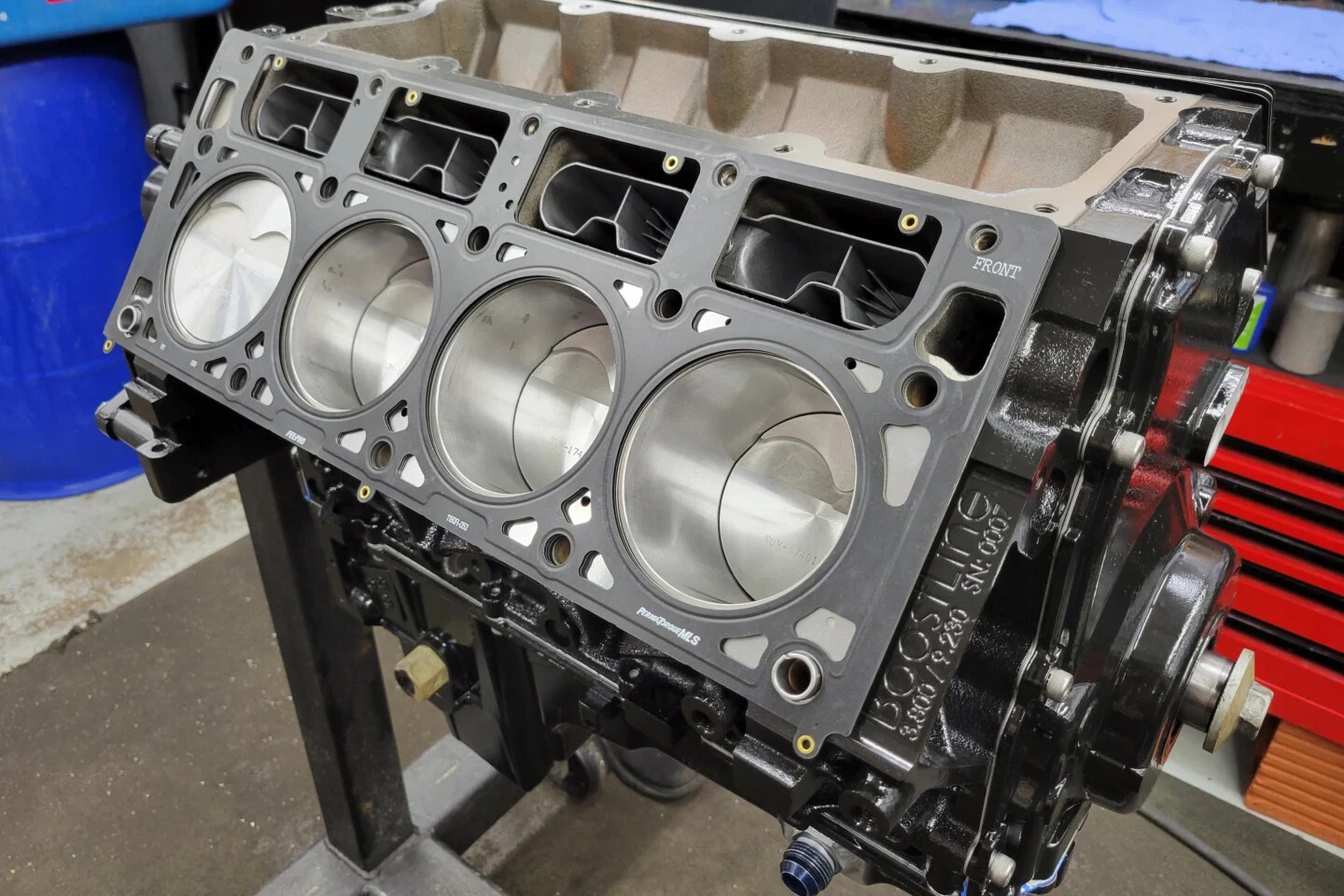

Our BoostLine Performance 5.3-Liter Test Mule

In order to hit the budget in our original build, we made some parts compromises. Obviously, everything worked out well, but we definitely had a few parts we wanted to upgrade for this test. So, let’s do a quick rundown of the long-block we’ll be using as our test mule once again. As we mentioned previously, the engine’s name — 007 — has less to do with James Bond and more to do with the fact that this was the seventh BoostLine Performance Street/Strip-series 5.3L short-block to be assembled.

Starting with a seasoned Gen-III 5.3-liter engine block, BoostLine cleaned up the decks, align-honed the mains, and torque-plate-honed the cylinders to a 3.800-inch bore. A rebalanced rotating assembly consisting of a set of forged 2618 pistons and 4340 H-beam connecting rods with upgraded ARP2000 rod bolts hanging off of a stock crank makes up the guts of the BoostLine short-block. The rotating assembly is held in the block with an ARP main stud kit.

As you can see, the serial number is where the engine got its name. It’s a simple, yet robust bottom end: stock 5.3 crank, forged H-beams, and forged 2618 flat tops. This short-block has already proven its mettle beyond 1,000 horsepower.

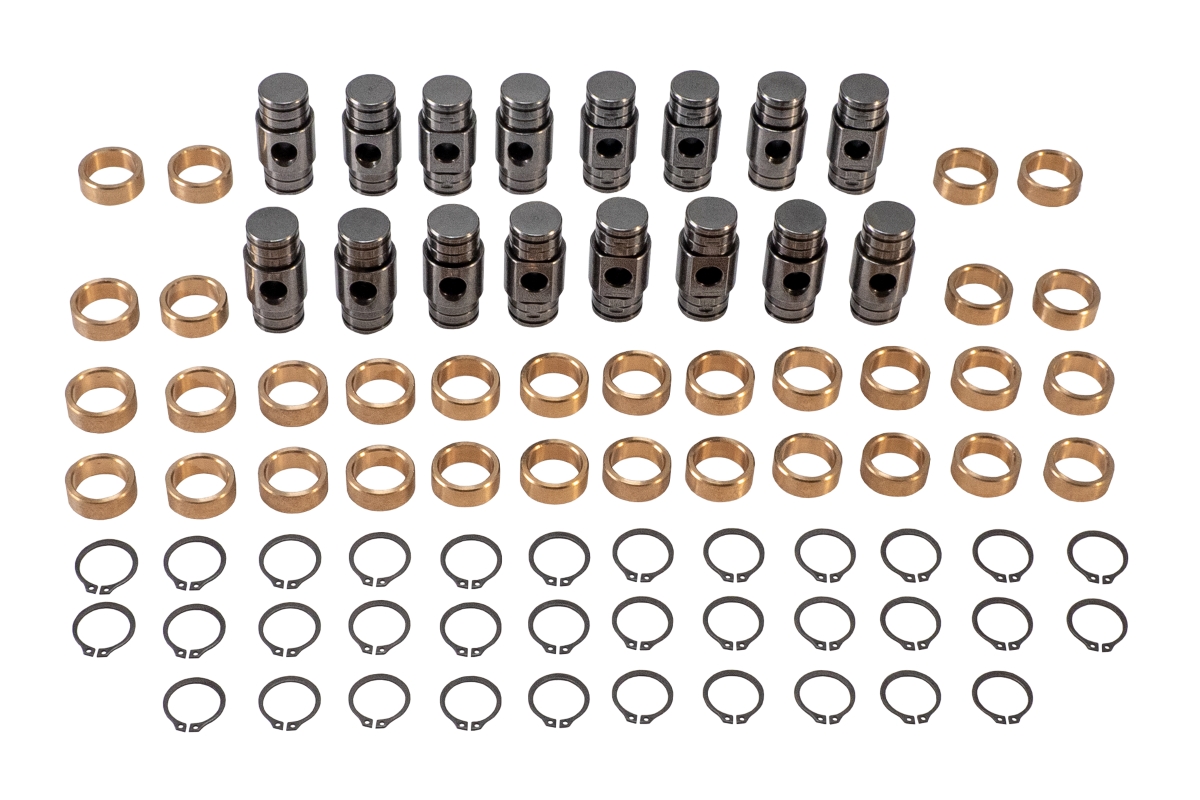

A set of cleaned-up stock 862 castings are retained with a set of ARP2000 head studs and sealed with .051-inch compressed-thickness MLS gaskets. Factory rocker arms with upgraded trunions are actuated by a set of Summit Racing’s “HDR Thickwall” 5/16-inch diameter, .105-inch wall-thickness pushrods sitting atop of Summit’s LS7 lifters and trays. A set of Summit Racing dual valvesprings keep the valvetrain under control.

Overall, the 007 long-block is a capable performer as we proved in the previous article. However, with the goal of maxing out a supercharger on the table, there were a few changes we wanted to make to the accessories on the engine to better support the project.

Optimizing the Intake Airflow

When it comes to intake manifolds in boosted applications, there are a lot of different opinions on what’s best, what matters most, and even on the material of the intake manifold itself. For us, we came at the intake manifold choice from a different angle. With F.A.S.T.’s new intercooler designed specifically for the LSXHR intake manifold, it was a no-brainer.

The FAST LSXHR is a polymer tunnel-ram-style intake manifold, available for the full range of LS port shapes. Obviously, for this application, we went with the 103mm cathedral-port variant (P/N: 146303). The polymer material is rated for up to 45 psi of boost pressure, and it helps eliminate heat soak thanks to the polymer’s thermal conduction properties.

The FAST LSXHR intake is a polymer tunnel ram style intake that is designed to work well in the upper RPM range, as well as withstand copious amounts of pressurization from a power adder.

The runner lengths have been optimized with trumpets to smooth incoming airflow, and are optimized for a 5,000- to 7,500-rpm power peak. While different velocity stack lengths are available to fine-tune the powerband, we won’t be using them at all. Additionally, the injector placements have been tweaked to aim the spray pattern in a more advantageous location. The LSXHR comes with a set of manifold-specific fuel rails to account for this tweak, and the plenum top comes with a 103mm opening out of the box. They have left enough meat on the throttle-body flange to port-match a 105mm throttle body.

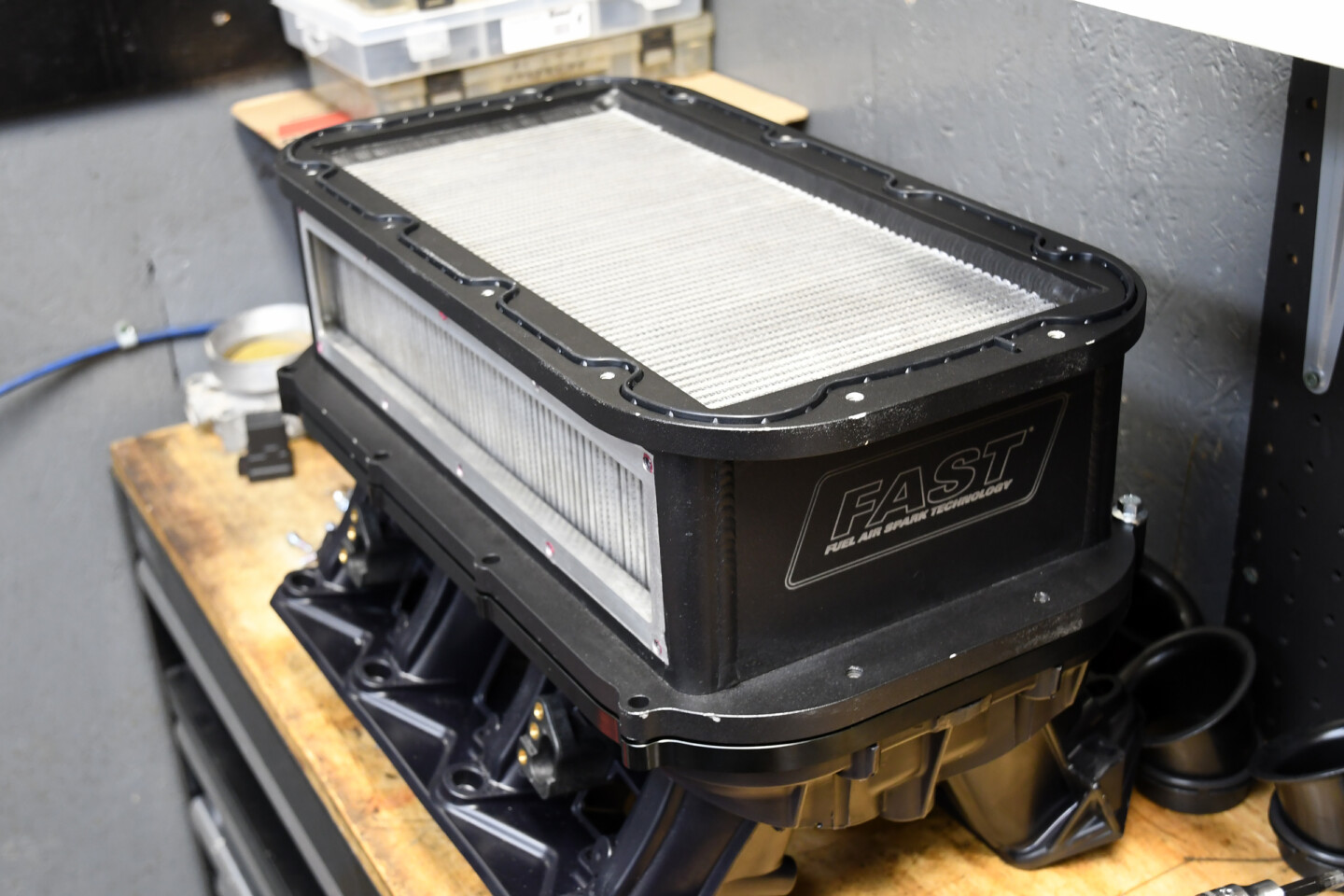

You might be wondering why we said we aren’t using the short, medium, or long velocity stacks with our LSXHR manifold. Well, that answer is easy: because we want to run FAST’s LSXHR Intake Manifold Intercooler (P/N: 148000). Designed to specifically fit the bolt pattern of the LSXHR lid, the intercooler core sandwiches between the upper and lower halves of the manifold, where the velocity stacks would normally be.

The LSXHR intake manifold also comes with tunable velocity stacks inside the plenum. Available in short, medium, and long (pictured here), in order to run the intercooler, we needed to remove them altogether.

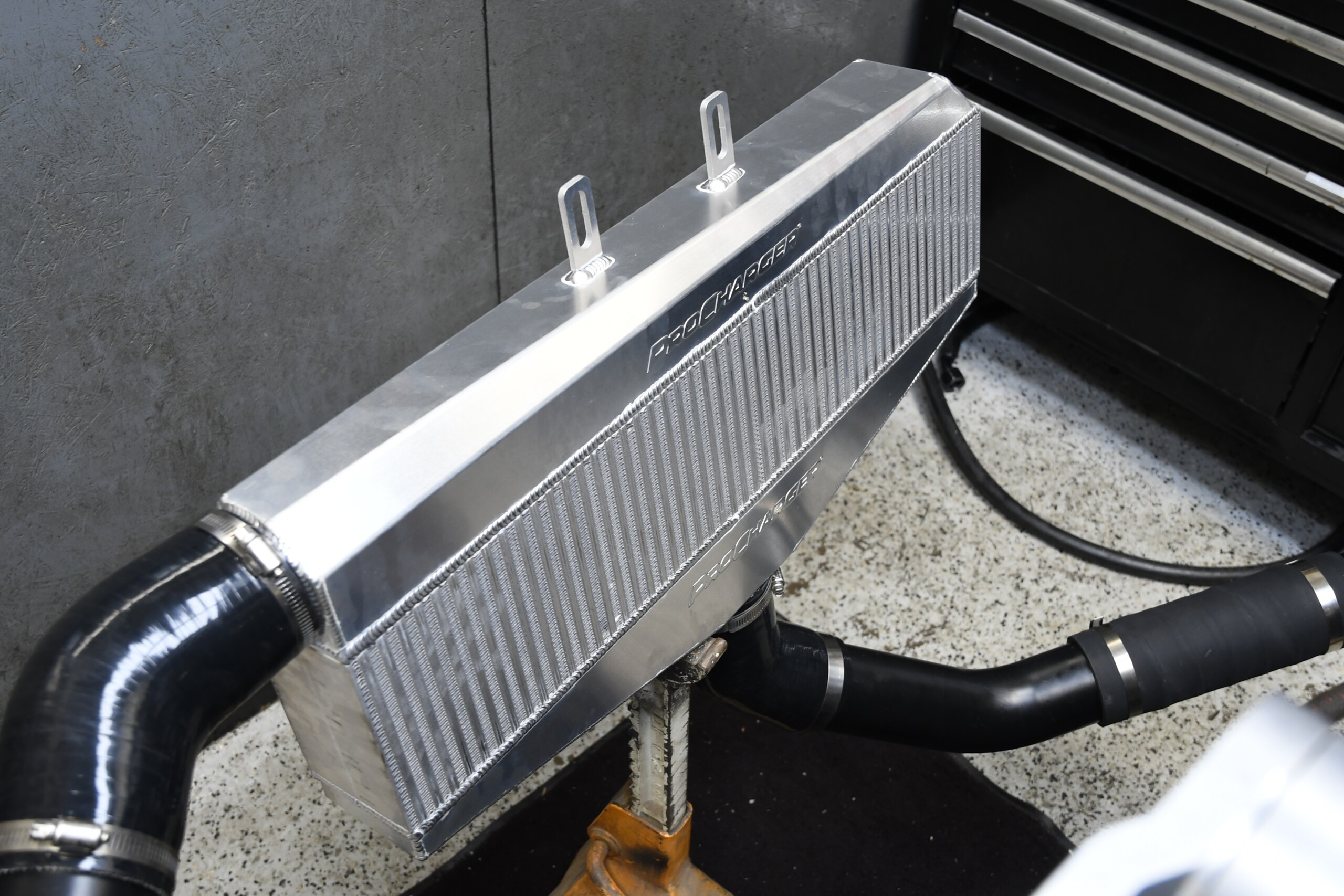

The 5.8-inch-thick intercooler core is an air-to-water design that requires no fabrication to install, other than making up some -16AN lines to feed the core. The bar and plate construction offers both high airflow and efficient water flow through the core, and has been tested up to 1,350 horsepower on a turbo application, with less than 1 psi of pressure drop across the intercooler.

The incredibly easy-to-install intercooler option is a much simpler option to cool the intake charge than the water-methanol setup we had on this particular engine in the first round of testing. The only compromise we had to make, if you can even call it that, was the removal of the velocity stacks in the LSXHR intake manifold. At well over double atmospheric pressure, it’s doubtful that we are giving up much performance at all by removing the stacks, especially compared to the gains we’ll see from the water-to-air intercooler.

This is the FAST air-to-water intercooler designed specifically to fit between the upper and lower plenums of the LSXHR intake manifold. It adds 5.8 inches to the height of the intake, boasts low pressure drop across the core, and a ton of cooling capacity.

Other Upgrades For 007

Since we had a Summit Stage II Turbo Cam in the engine previously, we decided to swap that out for something a little more supercharger-friendly. The Brian Tooley Racing Red Hot camshaft has .619 inch of valve lift on the intake side, and .617 on the exhaust, which isn’t much more intake lift than the turbo cam, but significantly more lift on the exhaust.

On the duration side of things, the Red Hot cam has 221 degrees of duration at .050 inch of valve lift on the intake, and 240-something degrees of duration on the exhaust, which works out to be five degrees less intake duration but 10-plus degrees of additional exhaust duration. Both of the cams have a 113-degree lobe separation angle. It’s fair to say that the Red Hot cam will be allowing a lot more exhaust out of the engine, to better suit the ProCharger.

The final change we made to 007 was the addition of an ATI Super Damper. The Super Damper has been a go-to for us for many, many projects — supercharged and otherwise — over the years. However, we went another step further with this one. Since the stock 5.3-liter crank doesn’t have a keyway cut into it from the factory, we took advantage of ATI’s crank pinning kit and pinned the crankshaft in place of cutting it for a Woodruff key.

The ATI hubs for LS engines come ready for a key or a pin, so half the work was already done. While we were able to get away with not pinning the balancer previously, since it was a turbo application, for a crank-hub-driven supercharger application, it’s an incredibly good idea to pin the crank, even if you aren’t looking to max out the supercharger. That way, you aren’t relying on just the press-fit of the balancer hub to the crank snout to prevent rotation.

Since the factory 5.3 crank relies solely on a press-fit to retain the damper hub, we used ATI’s crank pinning kit to install a crank pin to help resist the torsional forces exerted on the balancer while driving the supercharger.

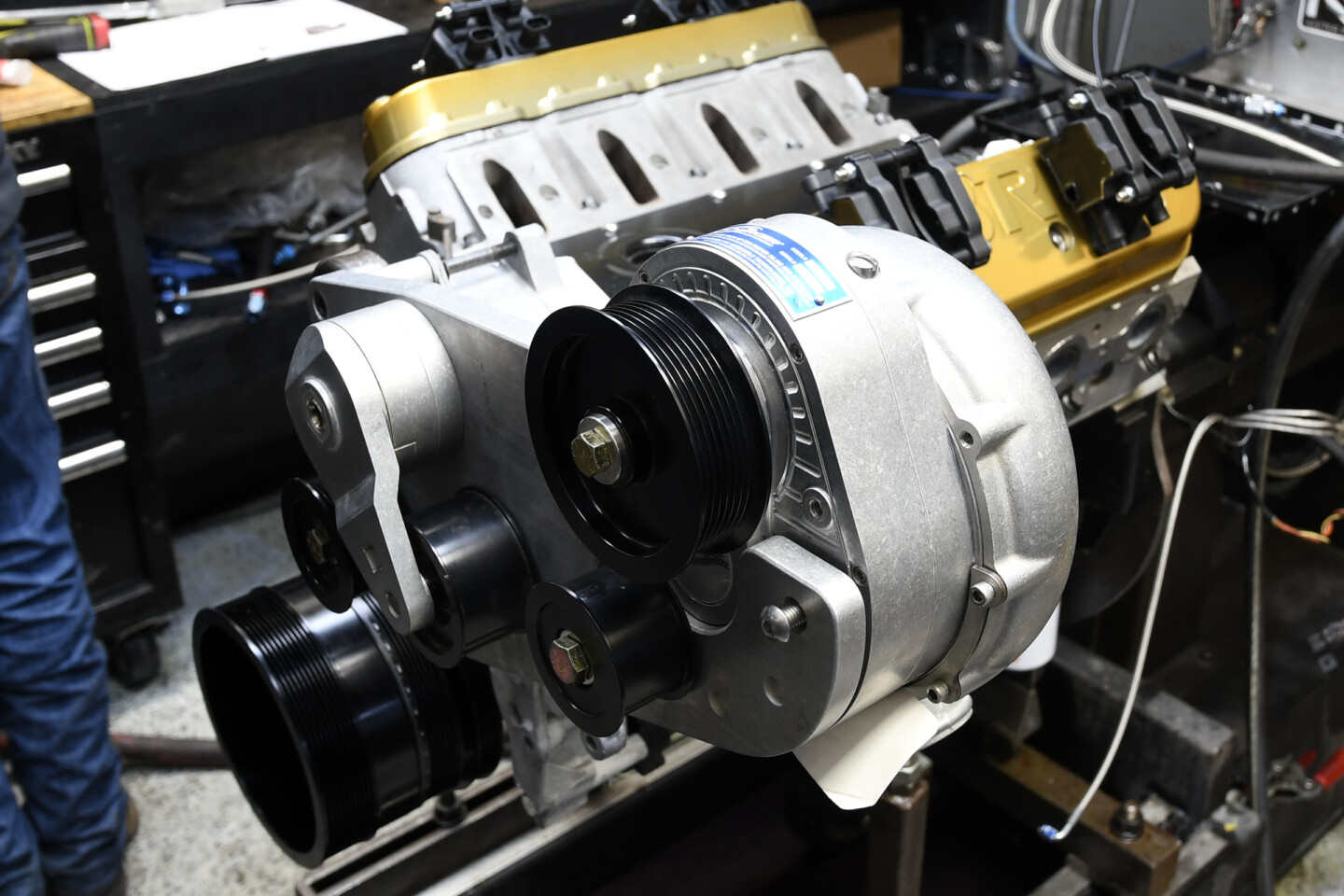

Fitting The Blower — The ProCharger P-1X

ProCharger has made the P-series superchargers for a long time. It’s a proven design that works well. But, over those years, it has been the subject of several internal upgrades. Currently, there is the basic P-1SC head unit, which has made lots of horsepower over the years and is still a great choice for lower-powered older engine designs. Then there is the P-1SC-1, which, as you might expect, is an upgraded P-1SC, and is a higher-output model that does great for bigger-power street applications. But, then, the big-dog of the P-1 series… the P-1X. Like all of ProCharger’s models, the “X” designation is the current badass of each lineup.

The P-1X has an entirely new impeller design that is more efficient and flows more, combined with a redesigned volute (compressor housing) to have a significantly higher maximum output. While the P-1X has the same nine-inch volute outer dimensions, internally, it is a whole new ballgame. So, let’s look at some of the critical dimensions and values of this new blower.

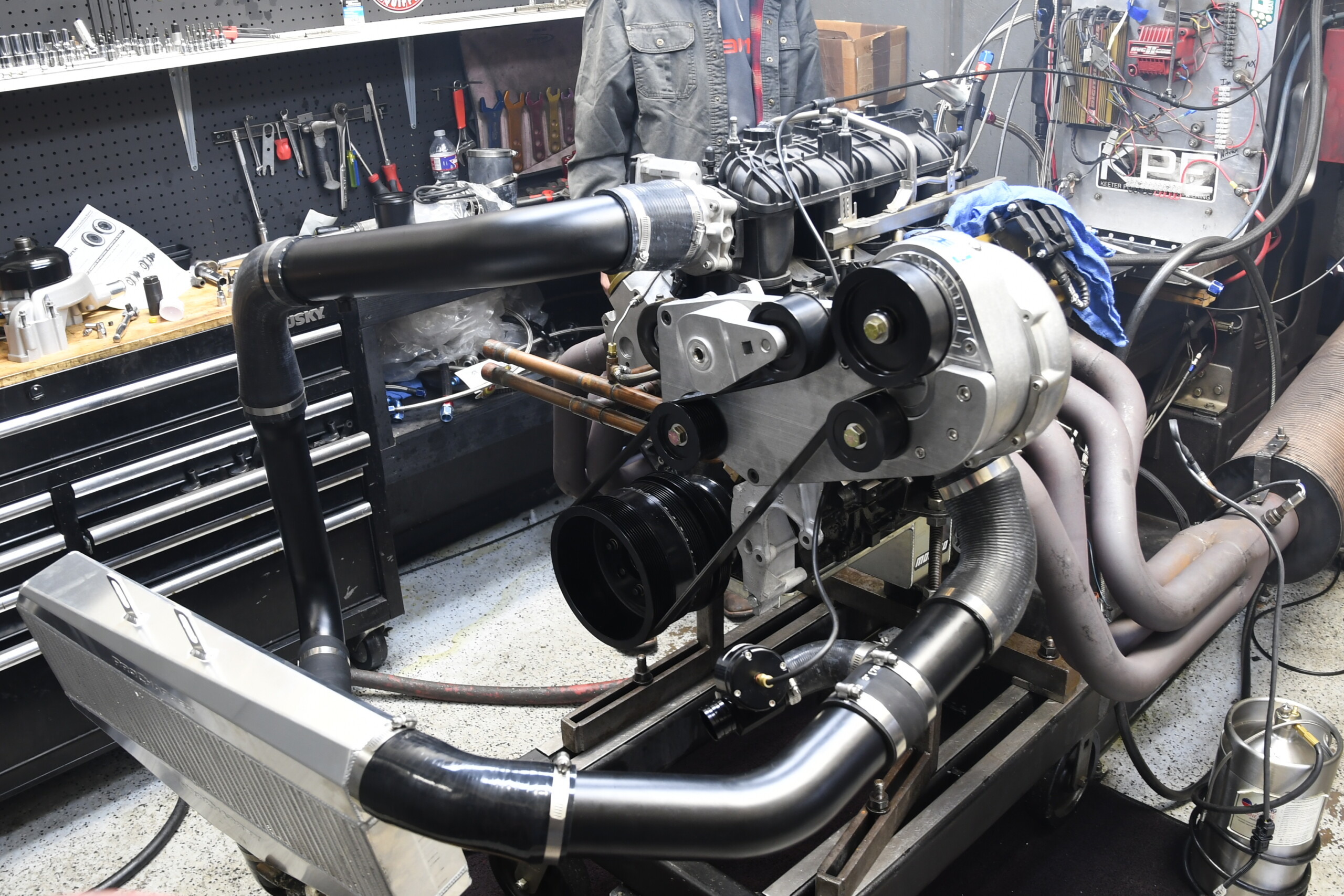

This is the ProCharger kit for GM 1500-series trucks. The standard kit is available with a P-1SC-1, with the P-1X as an optional upgrade. From ProCharger, the kit is designed to use a front-mount air-to-air intercooler, so we’ll test the kit in that configuration, too.

The new maximum flow listed for the P-1X impeller is 1,275 cfm, which is impressive, considering it has the same maximum impeller speed of 65,000 rpm as the P-1SC-1. The inducer and exducer are 0.20 inch and .31 inch larger, respectively, on the X model, but the inlet and outlet diameters are the same between models. Similarly, the P-1SC-1 and the P-1X share the same maximum boost level of 32 psi and the same internal step-up ratio of 4.10:1. On paper, the P-1X’s upgrade comes entirely in compressor wheel and compressor housing design, as the P-1X’s maximum horsepower is 125 horsepower more than any of the other trim in the P-1 lineup.

Because the P-1X has the same footprint as the other P-1 models, it is a direct upgrade for all of the existing kits. That also means that the huge application list for P-1 supercharger kits can be utilized with a P-1X. So, for our trusty 007 engine, we opted for a ProCharger kit for a half-ton GM Truck with the P-1X upgrade. That kit comes with a 4.15-inch supercharger pulley and a six-rib drive system. When combined with the 7.48-inch-diameter crank pulley, we’re significantly under the maximum impeller speed of the P-1X.

Since the P-1X supercharger was designed to share a lot of external dimensions with the other P-series superchargers, it is a direct swap. Besides being an upgrade option, it means you can retrofit any existing kit that uses a P-series blower. You can even have ProCharger upgrade your P-1SC head unit to P-1X spec.

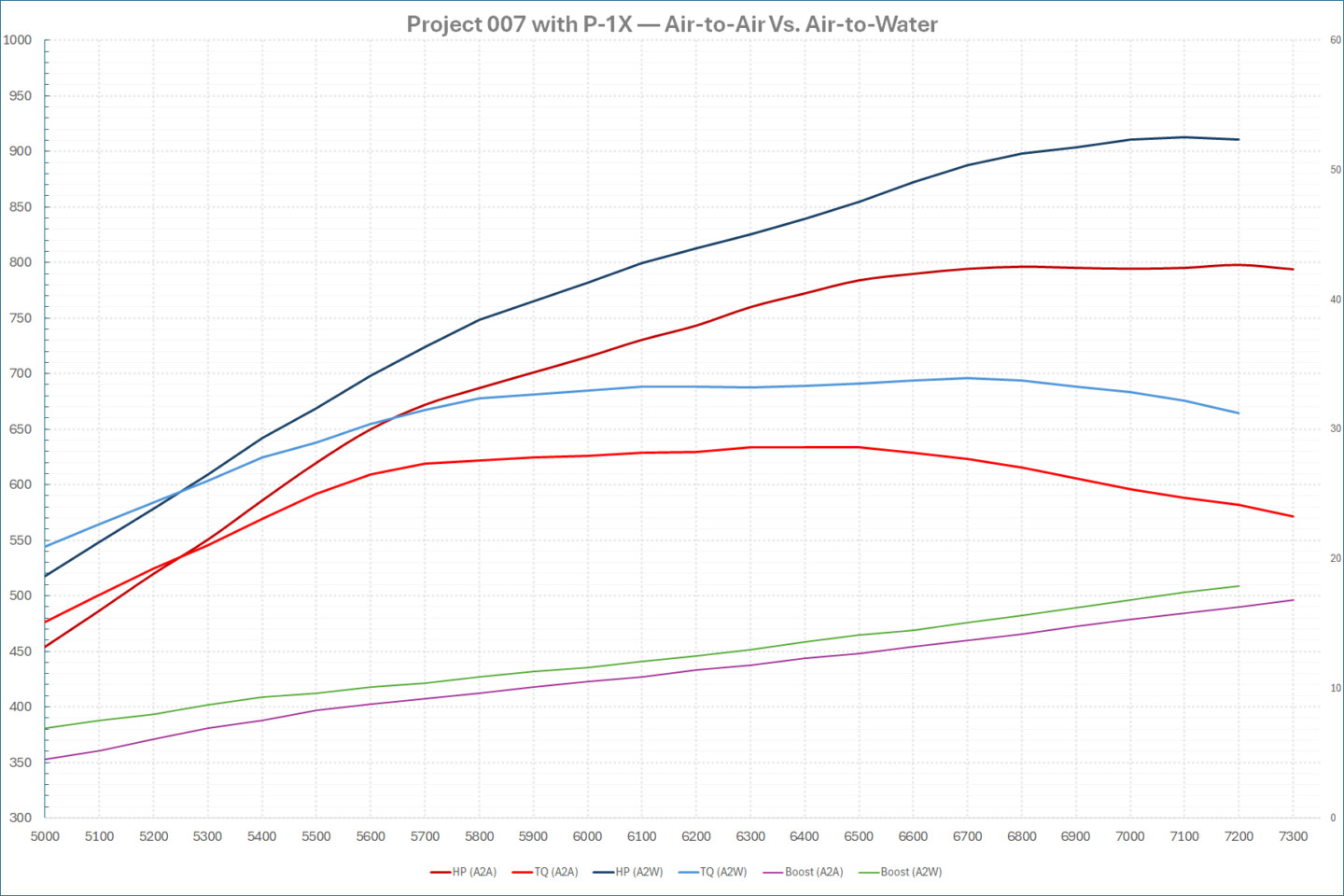

Air-To-Air Vs. Air-To-Water With A P-1X

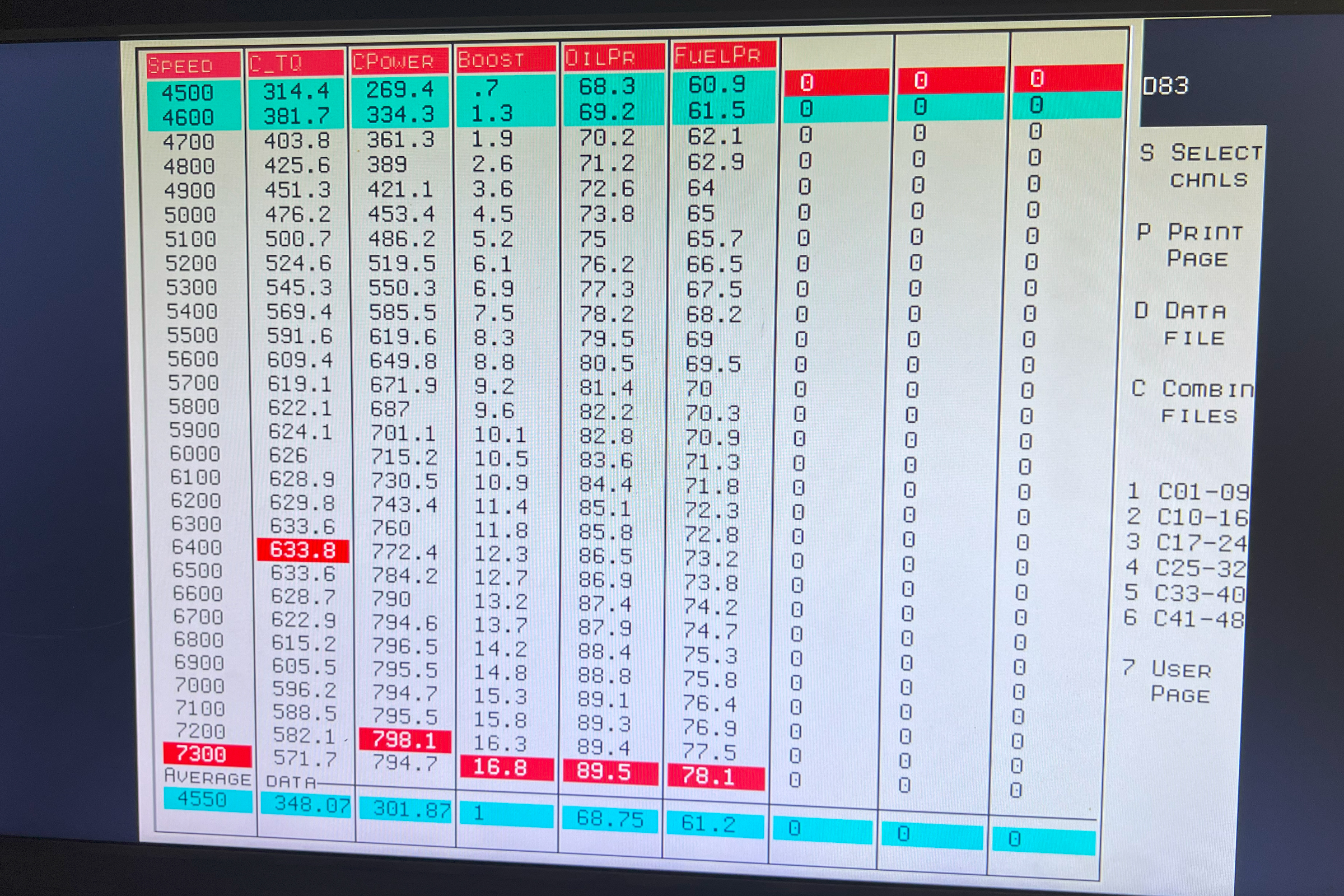

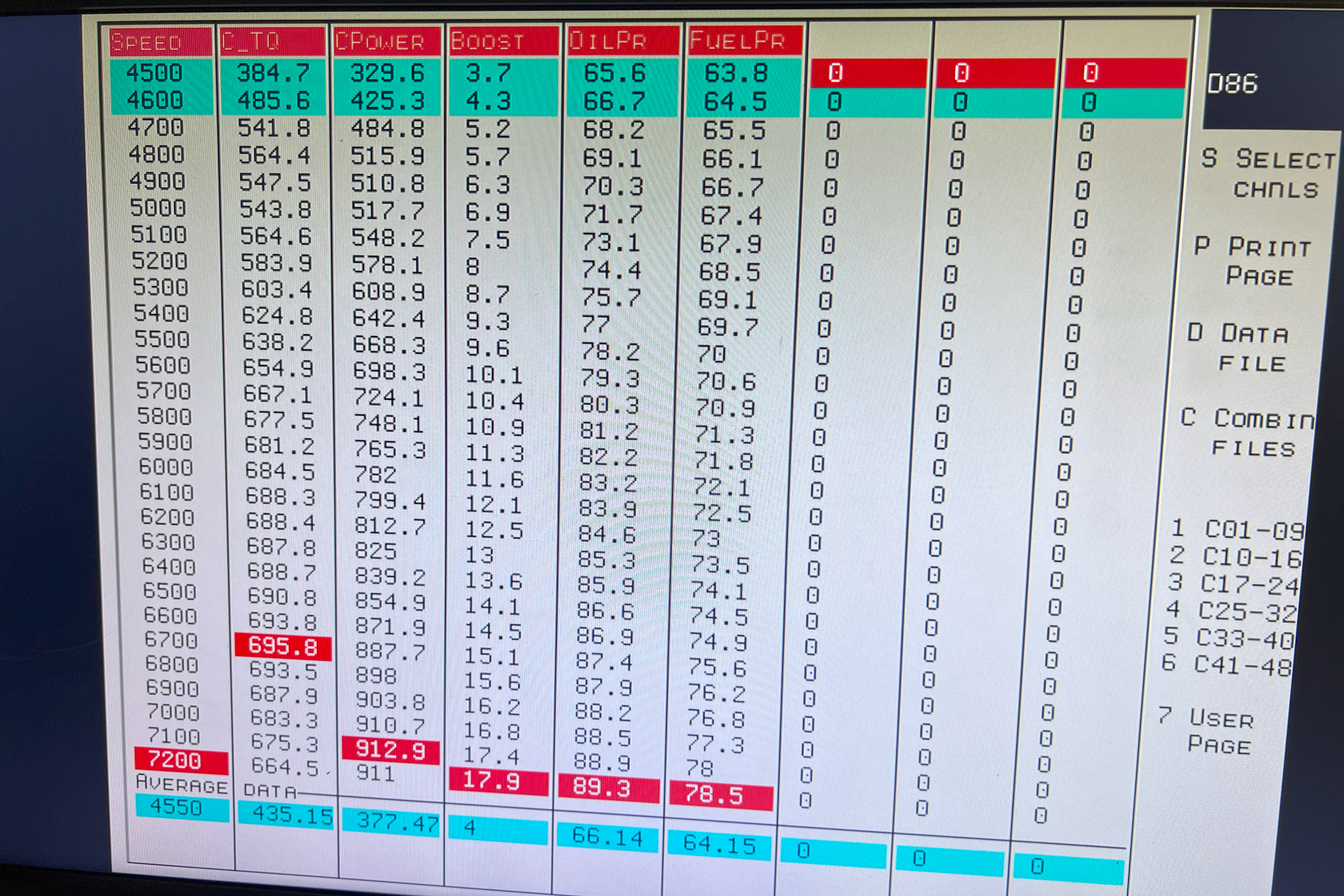

With everything installed, it was time to see what this 9.8:1 compression ratio engine, with a better cam, but stock 862 heads was capable of. Tuned on the same Holley Terminator X ECU as the last project, with 93 octane and BoosTane Professional in the tank, the first set of runs were completed using ProCharger’s supplied air-to-air intercooler and a stock truck intake, to get a baseline run. That initial setup saw numbers just shy of 800 horsepower at 7,200 rpm and 634 lb-ft of torque at 6,400 rpm. Not bad at all for a stock P-1x kit, exactly as it came out of the box, with a stock intake manifold, making 16.8 psi of boost.

The first round of testing as the kit came. 798 horsepower and 633 lb-ft of torque would make any half-ton pickup absolutely scoot. However, we want to make this combo fly.

With those runs complete, Tommy Keeter of KPE Racing swapped on the FAST LSXR intake with the intercooler sandwiched between the upper and lower, plumbed the water lines to the back of the unit, and fired up the dyno once again. Only three runs later, the numbers were stout: 912.9 horsepower at 7,100 rpm and 695 lb-ft of torque at 6,700 rpm, with peak boost pressure of 17.9 psi. As advertised, there was less pressure drop in the intake tract with the FAST intercooler, netting an additional pound of boost.

With the LSXHR and air-to-water intercooler in place, the engine saw a pound more boost at the manifold along with lower IATs, allowing Tommy to squeeze another 115 horsepower out of the combination at the same blower speed (well, technically slightly less blower speed). There was another 12,000 rpm of impeller speed available, but unforuntantely, we didn't have a larger crank pulley or a smaller blower pulley on hand to take advantage of that.

Unfortunately, that was the end of the testing, as we didn’t have a larger crank pulley or smaller blower pulley to swap on. At 7,200 rpm, we were only spinning the blower at 53,207 rpm — about 12,000 rpm under the maximum for the P-1X, and still well in the efficiency range of the compressor at only 17.9 pounds of boost. Oh, and at the peak RPM of the run, the IAT in the manifold, post FAST intercooler, was a scant 117 degrees Fahrenheit.

With there being some blower speed left on the table, we dare to say we could have flirted with the four-digit mark with this combination, had we actually maxed out the blower’s capabilities. Not bad at all for something that falls under ProCharger’s “Street” supercharger lineup. But, as technology marches on, the P-1X won’t be the king of the P-series for long, as the P-1R has been announced, and it should really shake up the small-supercharger world. We can’t wait to get our hands on one.

The final results of the P-1X testing on Project 007. As you can see, the air-to-water intercooler (blue traces) was worth significantly more power than the air-to-air-intercooled combination (red traces). Looking at the boost graphs, the benefits of a shorter intake tract volume with the air-to-water intercooler setup (green trace) can be seen as more manifold pressure at a given RPM point.